The Role of Manufacturing Drawing Software in Visual Communication

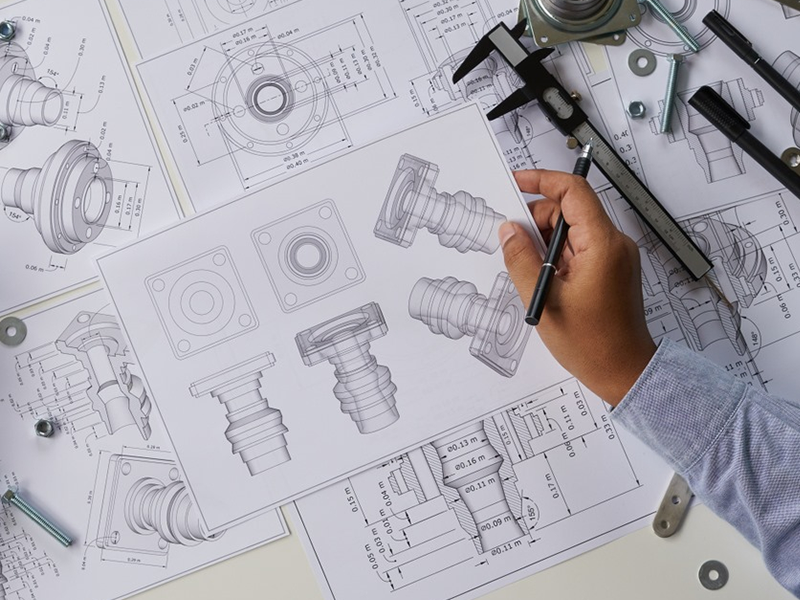

Manufacturing drawings are essential in product designs . Drawings like 2D manufacturing drawings and 3D mechanical drawings improve efficiency and lower errors in the manufacturing process by serving as a powerful communication tool for all parties involved. Therefore, using manufacturing drawings, you can save a lot of money and materials and obtain a product that meets all requirements.

This blog post will simplify a manufacturing drawing to be understood more easily.

Just dig in

What is a Manufacturing Drawing?

Manufacturing drawings are precise illustrations that guide the manufacturing of parts or objects. They offer exact specifications, such as dimensions, materials, tolerances, and assembly specifications, which are vital communication tools between manufacturers and designers. The drawings will ensure that the final product aligns with the design intent and the quality standards.

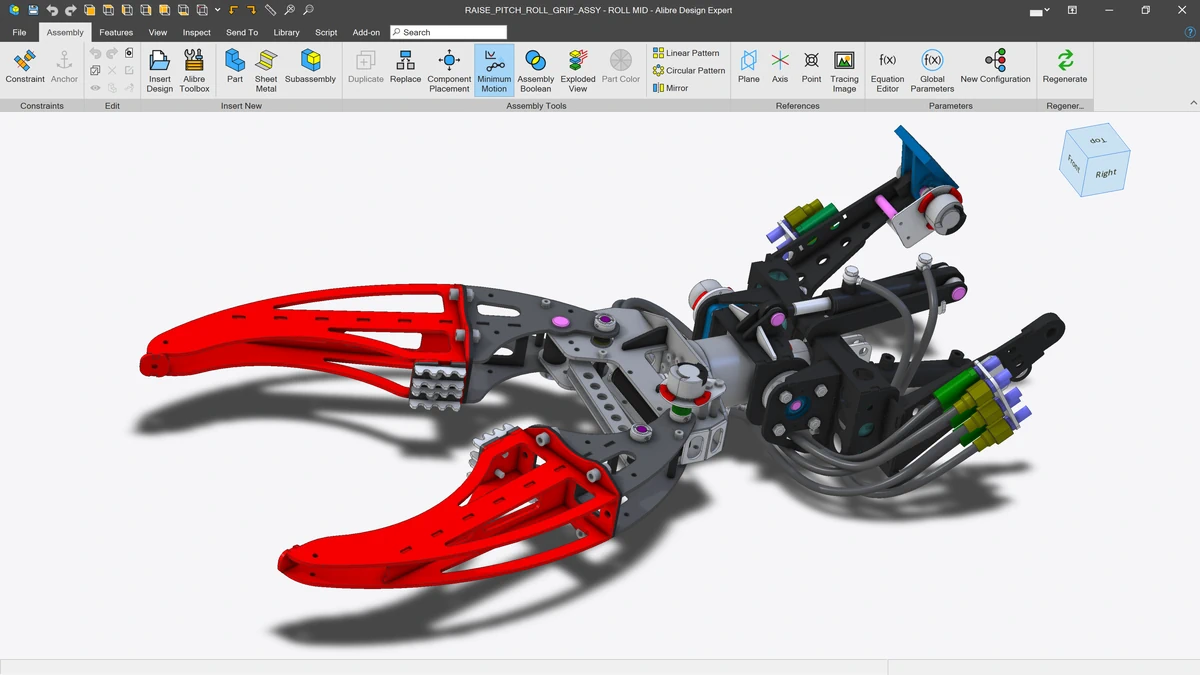

Designers use 3D mechanical drawing software to design, sketch, validate, and share ideas before production. Additional tools are offered and sometimes integrated into 3D engineering software to manufacture products using the CNC device and 3D printing. Mechanical drawing software is used in various industries, including automotive, industrial machine, and consumer design.

Deep drawing manufacturing is a standard method used in the industry to manufacture products. Complex parts can be achieved using deep drawing. The manufacturing process is widely employed in many sectors, including the automobile industry, the packaging industry, aviation, model construction, and the packaging industry. The most frequently produced deep-drawn components are car body parts faucets, bathtubs, and faucets, cooking pots, sinks, and plastic buckets.

Evolution of Drawings -Manufacturing Drawings

Before the initial release of the Computer-Aided Design (CAD) software program, Shop Drawings, Construction Drawings, and Installed Drawings were drawn by hand.

Do you remember offices with drawing boards, pencil sets, set squares, and erasers?

These are all things of the past; as technology has advanced, the drawings have also changed. Today, we can design buildings, machines, and products with particular characteristics in 2D and 3D graphics.

As CAD technology improved, the requirement for paper-based documentation diminished because the meta-data was recorded in systems. This increased efficiency increased projects in the form of 3D models incorporated into digital designs.

Suppose you think about the mess of managing huge piles of physical drawings on paper with notes on manufacturing. In that case, It's clear why digital systems started becoming the primary source for collecting product data.

Moving it up a notch makes it much more helpful when engineers are equipped with models, drawings, and descriptive designs. Visuals have become an essential element of product or manufacturing design because they enable engineers to comprehend what a final product or component will appear at a higher level of abstraction instead of requiring them to draw a picture of design and function from an inventory of manufacturing specifications.

Manufacturing drawings, including detailed specifications for components. Manufacturers, suppliers, and contractors utilize these drawings to comprehend the materials needed for production and the procedures to be followed during on-site installation and delivery of these components.

Is it quite interesting?

What makes a well-designed drawing software essential to manufacturing any item?

In short, it has advantages!

Advantages of Manufacturing Drawing -Navigating the World of 2D Manufacturing and 3D Mechanical Drawings

A well-designed set of drawings is essential to ensure efficient and cost-effective manufacturing. If you don't have a good idea, it could result in unsellable products or a manufacturing company that isn't willing to collaborate alongside you and a lack of direction for the future.

New designs for new products typically begin with a sketch of a hand that leads to more precise 3D models and even detailed manufacturing sketches.

Let's see what are the advantages of Manufacturing drawings!

Better communication

Manufacturing drawings are a method of communication between the maker and its owner. Therefore, it has to communicate the intent of the design to the maker in a way that they can comprehend.

Any crucial information that needs to be included could result in manufacturers relying on different standards or experiences to fill in the gap. This is a potentially tricky scenario since manufacturers only sometimes have a complete picture of the design or how it will interact with other components or equipment.

A professional and precise technical drawing provides all pertinent manufacturing details so that there is no confusion. Detailed part drawings coupled with a 3D manufacturing engineering drawing overview give the most effective of both sufficient detail to design the components correctly and an additional visual aid in understanding the larger picture.

Reduction in manufacturing time

A professional manufacturing drawing can significantly speed up manufacturing and save time in making corrections to errors.

If sketchy drawings are provided to manufacturers, they may have to create the pictures themselves to permit their employees to develop components. This can lead to long delays as the manufacturer must learn how everything works, and customers could be bombarded with inquiries during the procedure.

If the manufacturer uses a sketch that is not of the highest quality, it will be worse. The parts and products will be in a mess, with incorrect dimensions, finishes, fit and other mistakes due to poor drawings that could take weeks or even months to fix.

Whenever an explanation is required on an image, it can result in financial and time loss. Both the designer and the client must put off work to clarify what could have easily been included in the sketch.

Improvement in quality control

Controlling quality is essential for ensuring that the product conforms with its manufacturer and is consistent.

Manufacturing drawings are utilized together with inspection checklists and tests to make manufacturers accountable and clearly convey requirements. If a product requires a particular tolerance (such as when it needs to be compatible with other parts or equipment) It must be correctly calculated and documented precisely on the sketch. When the company's QC representative has signed off on the item, they verify that the part complies with the tolerances listed in the drawing.

If there is no tolerance data, a manufacturer may be required to follow each dimension of a plan as closely as they can. They believe these dimensions will be used to determine which parts to accept or not components. They could also think critical dimensions are unimportant and result in expensive work rework.

Precision dimensions are not always required. A professional designer will be able to calculate the most tolerant tolerance of a specific component or task to ensure the most efficient and cost-effective manufacturing. Inadequate high-precision dimensions (commonly included to cut design time) can cause confusion and add cost.

The ease of switching manufacturers

Any manufacturer must widely understand a quality manufacturing drawings. This implies that if one produces inferior components, consistently delays deadlines, or increases prices, the same picture can be referred to a different manufacturer, and the work can be carried on.

This is a further reason to hand over the creation of drawings for manufacturing to the manufacturer. They could use internal illustrations to influence negotiations, demand excessive charges for graphics or declare ownership of the pictures.

The result is that customers are often locked in with the manufacturers, who can determine the terms of their relationship.

Product design updates

After a product is prototyped, there will be changes, and the drawings set has to be updated to reflect any modifications that might have been necessary for manufacturing or functional purposes.

Up-to-date drawings can be essential if revisions need to be made following field performance evaluations.

For the upcoming software edition, the proper drawing set can help reduce time spent on duplicate work.

A poor set of drawings lost digital data, or a designer unable to reach them could make it easier to alter an item. Sometimes, creating the complete drawing set is the only way to progress. Investing in an expert set of designs initially comes with more than a professional layout. It can also save enormous amounts of money and time in the longer term.

Closing Thoughts

Making a quality set of drawings is essential in developing a product. Aliber manufacturing design software tool improves your process and prevents uncontrollable time frames and huge rework costs.

Contact us if you require manufacturing drawing software and learn about our products.

Last updated : 1 year, 11 months ago