Alibre Blog

3D CAD Software

7 months

Top 9 best 3D CAD software for beginners and professionals

If you are new to 3D CAD software or looking to upgrade your current tools, it's essential to find the best software that meets your specific needs.

With so many options available, it can be challenging to navigate through the choices.

In this article, we will explore the top 9 best 3D CAD software for beginners and professionals, helping you make an informed decision on which software is right for you.

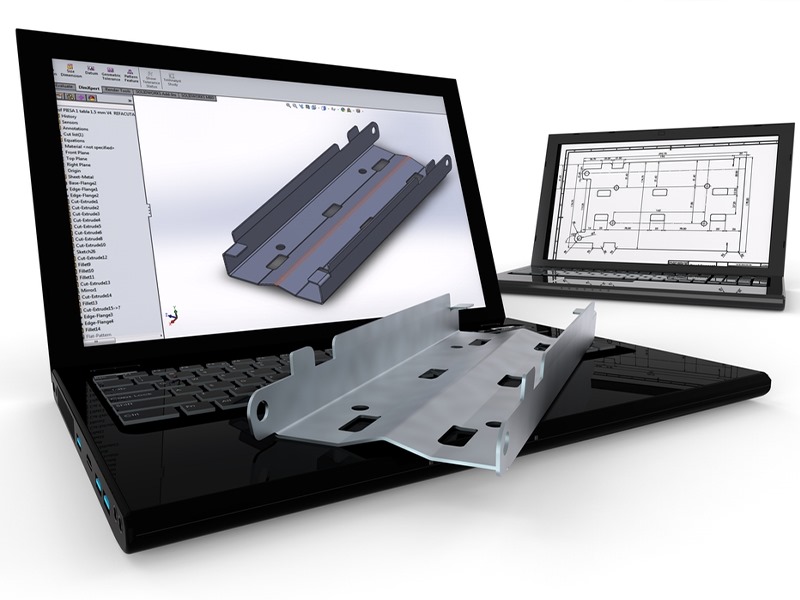

Choosing the best 3D CAD software for beginners and professionals is essential for a smooth and efficient design workflow. CAD is a vital tool for turning ideas into designs ready for production. It allows designers and engineers to make 3D models. These models can be viewed, improved, and tested. They can also be easily turned into real-world models using 3D printing or other manufacturing methods.

Embarking on the journey of learning CAD software may seem intimidating at first, but selecting the appropriate program can greatly ease the process.

Let’s explore the top 9 CAD software programs tailored for both beginners and professionals .

What is CAD Software?

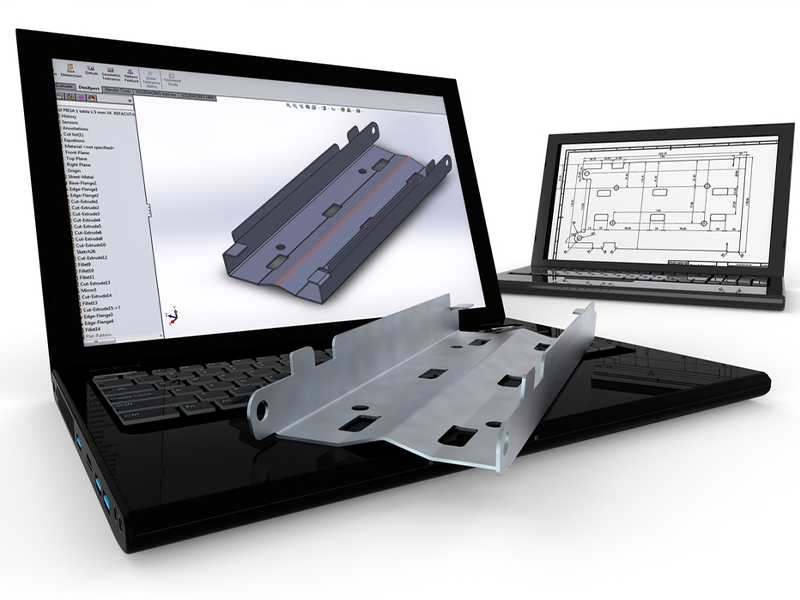

Computer-aided design (CAD) is a software-based tool that engineers, designers, architects, and manufacturers use to design and create objects, components, and systems. CAD software allows users to easily create 2D and 3D models, which can be used to document and refine the design process.

CAD software also stores geometric information, which can be used to share data across different platforms and devices. CAD has become essential in industries like engineering, design, architecture, and manufacturing, as it allows for the quick and precise creation of complex models and parts.

What are the applications and purposes of Computer-Aided Design (CAD) software?

- 3D Modeling with CAD Software

CAD (Computer-Aided Design) software empowers designers to create precise 2D and 3D models from scratch. It allows for customizations to meet specific requirements, making complex shapes that are difficult to create manually. Designers can quickly generate multiple designs for better product development, bridging the gap between initial concepts and production.

- Validation and Accuracy

CAD software can check the accuracy of designs and make sure they follow industry guidelines before they're 3D printed. CAD models can also be used for simulations, which helps you see how well a design will work in different situations.

- Effortless Changes

CAD software makes it easy to change different parts of a design, such as the size, shape, accuracy, how close it is to other parts, and other things. This lets people improve their designs without having to start over.

Best 3D CAD software for beginners and professionals |Alibre Design Software

Best 3D CAD Software for Beginners

SelfCAD

SelfCAD is an online tool for creating 3D models for 3D printing. It's perfect for beginners in 3D modeling because it's designed to be easy to use and learn. Even though it's not just for students, it does have advanced tools for making models, sculpting, and getting ready for 3D printing. SelfCAD uses a polygon mesh system for designing. This helps beginners learn the basics so they can move on to more complex design software later. SelfCAD can be used online or downloaded.

Sketchup Make

Sketchup is a free, user-friendly software that makes it easy to create models using surfaces. It provides a variety of beginner-friendly tools. To get started, choose a template that will walk you through the modeling process. SketchUp's strength lies in its extensive online database called 3D Warehouse. This database houses numerous 3D models, such as vehicles, buildings, and objects, which can enhance the realism of your projects.

TinkerCAD

TinkerCAD is an online 3D design tool that doesn't require any downloads. It's a great tool for beginners and students in education, as it allows you to create 3D models without prior experience. The software works by stacking virtual blocks together to build objects, making it easy to use the various 3D tools and bring your designs to life.

Best 3D CAD Software for Professionals

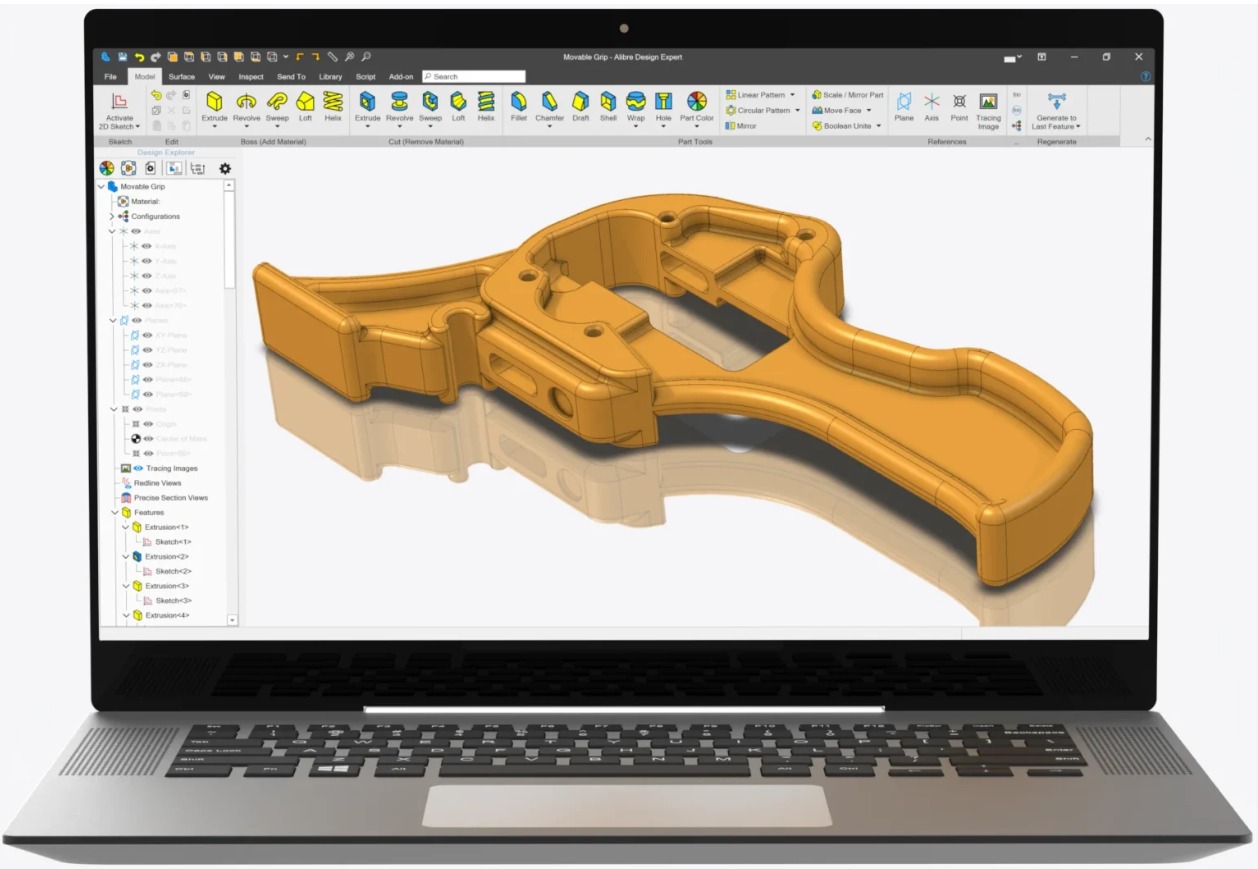

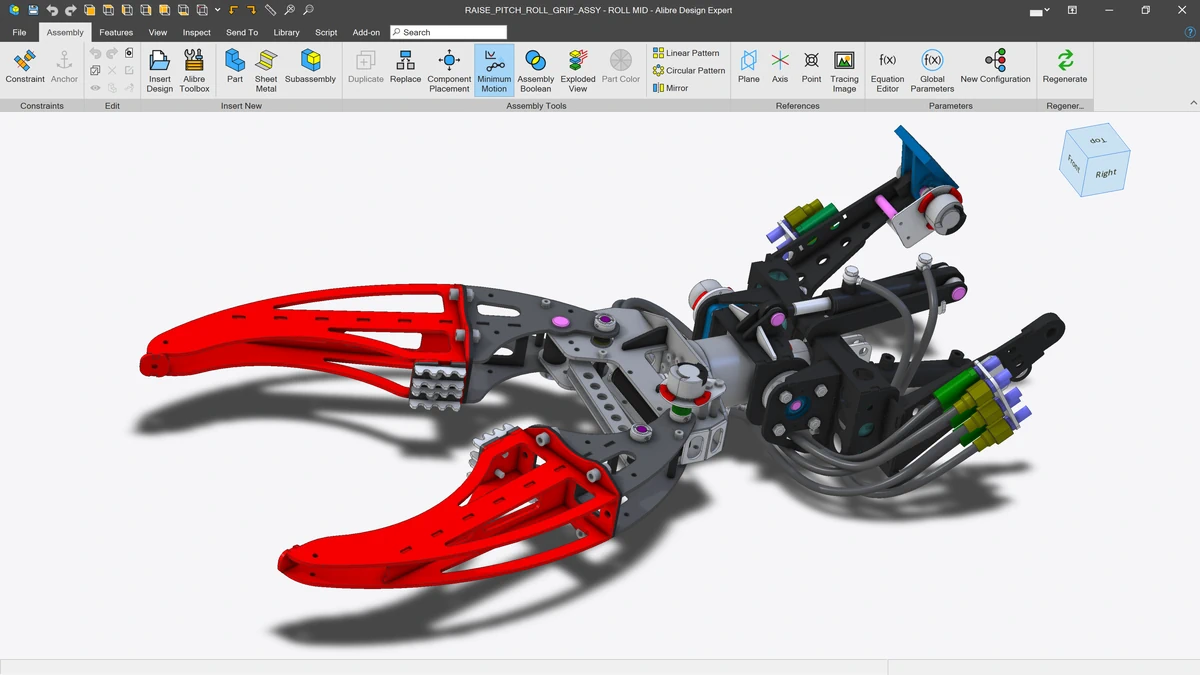

Alibre Design Expert

Alibre Design Expert is a top choice for small businesses and individuals because it's affordable and powerful for engineering tasks. It offers excellent value for the price and includes essential tools for mechanical engineering, design, and documentation creation. While comparable to Solidworks and Inventor, Alibre Design Expert is typically easier to learn. Key features include: Compatibility with major CAD formats, 3D design for parts and assemblies, Sheet metal design capabilities, 2D documentation creation, Excel-integrated part libraries, Variant management for different design versions.

Autodesk Fusion 360

Autodesk Fusion 360, a subscription-based software, stands out in additive manufacturing for its cloud-based capabilities. It empowers users with comprehensive 3D design functionality, including detailed modeling, online collaboration, parametric engineering, and sculpting. Fusion 360 exhibits versatility by supporting various file formats, enabling seamless design exchange. Additionally, it excels in 3D printing preparation, offering tools to optimize designs for fabrication. This cloud-based platform encompasses a comprehensive suite of capabilities, including 3D design, computer-aided manufacturing (CAM), computer-aided engineering (CAE), computer-aided design (CAD), and circuit design.

Onshape

Onshape is an all-in-one online platform for 3D design. It empowers users to design, simulate, review, and manufacture products seamlessly. The platform offers accessibility across various devices, including tablets, laptops, and smartphones. Onshape provides a comprehensive suite of tools, including a 3D printing library, dimensioning tools, a robust sketching environment, and scripting capabilities. This versatility makes it an optimal solution for a wide range of design and manufacturing applications.

Solidworks

Solidworks is widely used in industry and provides extensive tools for designing, testing, and visualizing 3D projects. It includes unique features such as a 3D sculptor, DraftSight for 2D drawing, and a tool for mold creation. Solidworks offers advanced capabilities, such as automatic animation generation, surface modeling management, and the ability to create realistic renders. This makes it a comprehensive platform for product design, simulation, and analysis.

AutoCAD

AutoCAD, a widely-used CAD software, specializes in creating architectural designs. It also excels in generating mechanical drawings from 3D models. However, engineers and designers prefer 3D CAD programs for mechanical design, rather than AutoCAD.

Autodesk Inventor

Autodesk Inventor is a premium CAD software specifically designed for product designers and engineers. It offers advanced capabilities for 3D mechanical design, simulations, tool creation, and design sharing. Inventor streamlines product development by saving time and resources. Its 3D digital modeling allows for immediate validation of designs in realistic scenarios, eliminating the need for prototypes. It offers comprehensive simulation tools for analyzing movement, bending, and stress, enabling optimization of designs. Additionally, its intuitive editing features and advanced surfacing tools facilitate the creation of highly detailed product components.

Solid Edge

Siemens Solid Edge is a comprehensive software solution for the entire product development process, empowering engineers with tools to optimize product design. It features advanced tools for mechanical, electrical, and PCB design. Moreover, it integrates simulation analysis and provides advanced capabilities for both conventional and contemporary manufacturing techniques, enabling engineers to produce products with enhanced efficiency.

Conclusion:

To select the best CAD software for beginners, consider these key factors: Simplicity: Choose software that is intuitive and easy to navigate for newcomers.

Features: Ensure the software offers essential features for basic CAD projects.

Compatibility: Check if the software works with your operating system and other design tools.

Support: Look for software with helpful resources and documentation for beginners. For those starting out, free and open-source options like FreeCAD, TinkerCAD, and SketchUp Free provide a great foundation. By assessing your needs and exploring the available options, you can find the ideal CAD software that empowers you to transform your designs into reality.

Check out Alibre Design and other leading 3D CAD software options on alibre.in. Get detailed information and trial versions today!

3D CAD Software

7 months

Best 3D Modelling Software for Architecture Design in 2024: Top Choice

If you are searching for your Best 3D modelling software for architecture design, your objective will be to bring your ideas for design to life, regardless of whether they are 2D or 3D models of buildings.

Have you ever wondered how architects transform their amazing designs into real structures before construction even begins?

It's all thanks to the magical world of 3D modelling! This is where creativity meets technology to build stunning digital worlds.

In the toolkit of architect design software,3D modelling is at the top of the line in modern technology, which is crucial in bringing imaginative designs. From creating conceptual concepts digitally to creating advanced models ready for production and an immersive architectural image, 3D modelling software is an essential component of the modern workflow of architects.

But what are the distinct characteristics of the various 3D modelling applications and what makes the best ones apart?

When it comes to achieving quality architecture, the selection of 3D modelling software becomes an essential choice.

In this article, we will read the Best 3D construction modelling software for you and how Alibre Design Expert stands out as an advanced iteration of Alibre Design, equipped with additional features and capabilities tailored for users seeking heightened functionality.

Why should you use the best 3d modelling software for architecture?

Modern building architectural design and construction projects heavily rely on documentation provided by contractors and subcontractors. Nowadays, Computer-Aided Design (CAD) programs are commonly used by experienced designers to create construction documents and plans. These programs allow designers to showcase plans, elevations, working drawings, sections, and related information, as well as prepare budgets. These documents are not only crucial for estimating project costs, but also play a significant role in marketing the final product.

Traditional architectural design methods can be time-consuming, but in today's competitive marketplace, time is money. To stay competitive, designers need to use their time efficiently. 3D modelling techniques and CAD programs can save a lot of time and money by helping designers create accurate documents and gather all the necessary information to promote the finished product.

The benefits of using architectural 3D models include:

- Improved visualization of the final building or product.

- The ability to identify and correct errors during the design process.

- Optimal use of materials and cost reduction in the project.

- Virtual tours and walk-throughs.

- Efficient promotional and marketing tools.

- Minimizing the need for design revisions.

Using 3D modelling for architectural construction and design allows architects to make constant changes as the model develops, ensuring that the design meets the client's requirements. This not only results in a better final design but also maximizes the efficient use of materials. It's no surprise that this type of software and procedure is widely popular in the design and construction industry today.

Importance of choosing the right 3D architecture software

In the dynamic world of 3D Modelling, the choice of software can make or break your creative endeavors. This blog unravels the critical importance of selecting the right 3D modelling software based on specific purposes, acknowledging that one size certainly does not fit all.

1. Seasoned Professionals: Understand the need for advanced features in CAD software for professionals who require precision and complexity in their designs.

2. Project-Specific Requirements

- Product Design: Dive into the specialized features of product modelling software, catering to the intricate details required to create prototypes and manufacturing-ready designs.

- Architectural Planning: Discover how architecture-centric 3D modelling software facilitates accurate representation and visualization of architectural designs, from conceptualization to execution.

3. Efficiency in Workflow

- Time-Sensitive Projects: Discuss the significance of software streamlining workflows, particularly in time-sensitive projects, ensuring efficiency without compromising quality.

- Collaboration Tools: Highlight the importance of collaboration features for teams, emphasizing seamless communication and real-time sharing of design elements.

4. Rendering Capabilities

- Realism in Visualizations: Examine the impact of rendering capabilities in creating realistic visualizations, which are crucial for industries like animation, where lifelike scenes and characters are paramount.

5. Scalability and Flexibility

- Future-Proofing: Address the need for scalable solutions that adapt to evolving project requirements and technological advancements.

- Multi-Purpose Functionality: Emphasize the benefits of versatile software that can serve multiple purposes, offering a broader range of creative possibilities.

6. Budget Considerations

- Affordability vs. Features: Discuss the delicate balance between budget constraints and the need for feature-rich software, guiding users to make informed decisions based on their financial parameters.

Advanced architect design software Tools for Professional Architects

Design software for the digital age is essential in the contemporary architecture field. The clients expect more than just concept sketches, blueprints, or physical models. They would like to see virtual representations that provide greater detail. By using 3D modelling it is possible to design interiors and fill your structures. Some of them let you alter lighting effects and consider how external forces affect the building.

Here I am introducing Alibre Design Expert, the best 3d modelling software for architecture design and let see how this tool automates routine procedures and how the designs can be delivered to clients more quickly and have a better process.

Alibre Design Expert

Alibre Design Expert is a leading choice for medium and small size firms (SMBs) and for individuals because of its affordable cost of ownership and outstanding performance in engineering tasks. It's described as having an outstanding price-to-performance ratio, and is focused on offering all of the tools that are high-value needed for mechanical engineering design and documentation. It's similar to tools, such as Solidworks and Inventor and has a less steep learning curve.

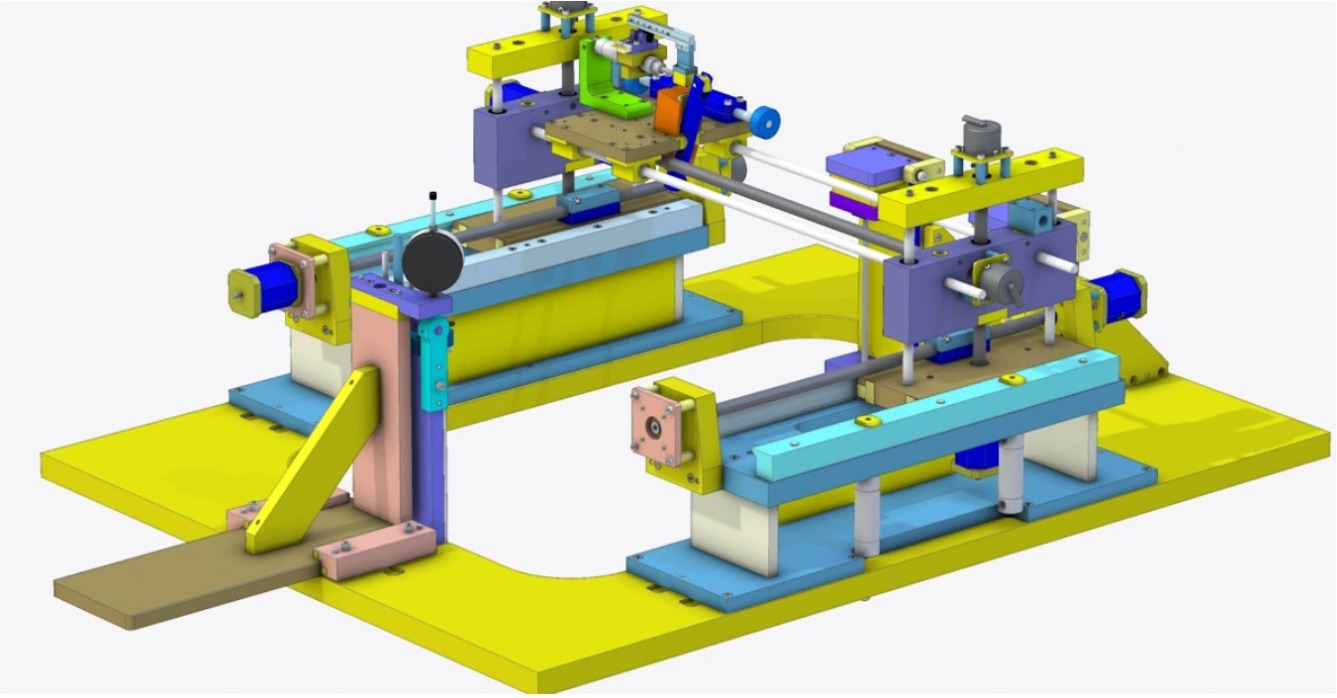

Alibre Design Expert supports key capabilities for data-driven engineering and design, including access to all the major CAD formats, parametric 3D design of assemblies and parts sheet metal design 2D documentation, excel-driven parts library, variation management rendering and Python-based scripting languages to automate.

Key features include

- Extended File Format Support:

Alibre Design Expert typically offers an extended support for file formats which allows the users to transfer and upload a range of different file types. This increases the interoperability of the other CAD software and allows collaboration between multi-software environments.

- Global Design Variables:

Global design variables The global design variables in Alibre Design Expert enable users to specify parameters at the highest level, which makes it simpler to manage and change different aspects of a design. This feature helps streamline the process of designing by offering central management of the most important variables.

Alibre Design Expert includes advanced tools for modelling sheet metal. Users can design, modify, and then unfold sheet metal parts, which allows them to design complex components that are employed in applications like enclosures, brackets, and various structures made of sheet metal.

- Photorealistic Rendering:

The capabilities of photorealistic rendering in Alibre Design Expert enable users to create high-quality and realistic 3D models. This feature is crucial for creating captivating presentation materials, marketing materials or reviews of design.

- Design Configurations:

Design configurations let users make and manage multiple designs in the course of the project. This is useful to explore design options as well as creating different versions of the product or adapting variations to customer or manufacturing requirements.

- Alibre Toolbox:

Alibre Toolbox is a set of common parts and fasteners which are included with the Alibre Design Expert. It includes a catalog of common components like bolts, nuts screws, and other typical components, which can be used to save time while making sure that designs are consistent.

- Motion for Screw, Gear, Pulley

Alibre Design Expert includes motion simulation tools for components such as gears, screws, and pulleys. This feature lets users examine and visualize the movements of these mechanical components in an assembly, assisting to ensure their functionality is correct and identify any potential problems.

Conclusion

Selecting the right software can be an overwhelming task, particularly when prices are high. But, believe us, the Alibre Design Expert cost is well worth the outcome. 3D modelling is a skill on its own, and requires an exceptionally creative mindset by the artist.

Happy designing!

3D CAD Software

7 months, 1 week

Introducing the best 3D Rendering Software for product design in 2024

In dynamic design, 3D rendering software transforms digital models into visually stunning, lifelike images. Whether you're an architect, product designer, or engineer, understanding the essence of 3D rendering software is crucial for bringing your creations to life. This guide will also delve into the best 3D rendering software for product design, empowering you to make informed decisions and achieve optimal results in your creative pursuits.

What Is 3D Rendering Software for a product design?

3D product rendering (or visualization) involves creating realistic or stylized images using 3D models and specialized software, resulting in a "3D render." The key benefit of this technology is that it allows you to see a product's appearance before it's physically made. You can explore various color options, perspectives, and environments, viewing the product as a whole or zooming in for detailed shots. This enhanced visualization provides marketers with early visual assets for promotions and enables manufacturers to assess product designs accurately.

How are 3D Renders made?

3D renders are created through a process that combines technology and artistry. The main steps are:

Modeling: Using software, a 3D representation of the object is created as a mathematical model.

Texturing: Textures are added to the 3D model's surfaces to make them look more realistic.

Lighting: Lights are strategically placed and adjusted to create a realistic lighting environment for the 3D scene.

Camera Setup: Setting up camera viewpoints is essential for controlling how the 3D environment is captured and shown.

Computer-Generated (CG) Rendering: Using computer software, 3D models and scenes are converted into 2D images, creating the final rendered image.

Post-Production: After initial rendering, this stage involves editing and refining the output with visual effects using image editing tools like Adobe Photoshop.

Who Uses 3D Product Rendering?

Computer-Generated Imagery (CGI) has become increasingly important in different fields. It has a significant impact on industries that use product rendering, particularly:

Product Manufacturers: CGI assists in product design, development, and marketing materials creation. It offers flexibility throughout product life cycles.

E-commerce Platforms: CGI is widely used by these platforms. Vendors provide 3D models for creating realistic product renders. Augmented Reality (AR) is used to showcase products in immersive experiences.

Retail Companies: CGI is advantageous for retailers because of its reusable assets. Faster production of large-scale imagery without transportation limitations, Integration with AR and VR technologies

Entrepreneurs: Entrepreneurs use CGI (3D modeling and rendering) to accelerate product launches. They can create high-quality visuals showcasing products in various settings, even before production or distribution. This allows them to launch websites and marketing campaigns while securing funding through crowdfunding.

Marketing firms greatly benefit from 3D rendering for two main reasons:

Time Savings: Agencies can obtain product visuals before manufacturing, significantly reducing lead times.

Creative Flexibility: 3D rendering offers boundless creative options. Artists can display products from any angle and in any setting, allowing for exceptional customization and visual impact.

What is the best software for 3D product design?

Alibre has many key features and elaborate on how they contribute to an efficient and powerful 3D rendering software . Let's break down !

1. Powerful 3D CAD Software:

Alibre Design is a robust 3D CAD software for mechanical design, prototyping, and manufacturing. Its capabilities go beyond just rendering, encompassing the entire design and engineering process.

2. Ease of Learning and Use:

Alibre Design prioritizes user-friendly features, ensuring that designers can quickly grasp the software regardless of their experience level. The easy-to-learn interface facilitates a smooth user onboarding process, reducing the learning curve.

3. Straightforward Workflows and Modern Interface:

The software is built on a modern interface, emphasizing straightforward workflows. This modern design enhances the user experience and ensures that the design process is intuitive and efficient.

4. Parametric and Rules-Based Modeling:

Alibre Design excels in parametric and rules-based modeling, allowing users to create complex mechanical systems easily. This feature enables the efficient management of design complexities, providing flexibility and control in the modeling process.

5. Dedicated Tools for Various Design Aspects:

Alibre Design offers dedicated tools for modeling, sheet metal design, assembly, drawing, rendering, and data/logic-driven design. This comprehensive suite of tools ensures that designers have specialized functionalities for every stage of the design process, including rendering.

6. Industry-Leading Interoperability:

Interoperability is a key strength of Alibre Design, enabling seamless collaboration with other design and manufacturing tools. This ensures designers can work across various platforms and integrate Alibre Design into existing workflows.

7. Native Python-Based Scripting Language:

Alibre Design goes beyond standard functionalities with a native Python-based scripting language. This feature allows for automation, customization, and scripting, giving users the flexibility to tailor the software to their specific needs and automate repetitive tasks.

8. Refined Over 24 Years:

The longevity of Alibre Design, refined over 24 years, speaks to its reliability and continuous improvement. This extensive refinement process ensures that the software evolves with industry needs, incorporating user feedback and technological advancements.

9. Drive Innovation Across Design, Manufacturing, and Marketing:

Alibre Design is a tool to drive innovation across design, manufacturing, and marketing processes. By offering a comprehensive set of features, interoperability, and automation capabilities, the software becomes a catalyst for creativity and efficiency.

Rendering Software for Sketchup

As technology advances, 3D renderings become increasingly lifelike. In the future, the distinction between real-world images and computer-generated graphics may become indistinguishable. Despite being widely used in architecture and design, Sketchup has limited rendering capabilities. However, its user-friendly design creation interface makes it a popular choice among designers.

Why is 3D Rendering Software Important?

Visual Communication: 3D rendering software allows designers to clearly and accurately communicate their concepts. It helps create lifelike representations of architectural plans, product designs, and industrial models, providing a visual experience that surpasses 2D drawings.

Design Evaluation: Rendering software empowers designers to assess their creations from multiple perspectives, in various lighting conditions, and with different material choices. This facilitates the early identification of potential problems, enabling designers to refine their designs before proceeding to manufacturing.

Client Presentations: Using realistic digital models (renders) in presentations helps architects, designers, and marketers better convey their concepts to clients. By seeing the designs in a lifelike manner, clients can more easily understand and appreciate them, resulting in increased satisfaction and collaboration.

Marketing and Promotion: 3D renders play a crucial role in marketing and promotion. They enable businesses to showcase their products or architectural plans in a visually captivating way. This attracts potential customers and investors by vividly demonstrating the features and benefits of the designs.

Conclusion:

Alibre Design transcends the traditional boundaries of 3D rendering software by providing a holistic 3D CAD solution. Recognized as the best 3D rendering software for product design, its focus on ease of use, parametric modeling, dedicated tools, interoperability, scripting, and continuous refinement positions it as a versatile and powerful tool for designers across various industries.

Connect with Alibre, the leading provider of best 3D rendering software for product design. Their advanced software enables you to elevate your design concepts, providing a complete toolkit for innovative and streamlined product development.

3D CAD Software

7 months, 1 week

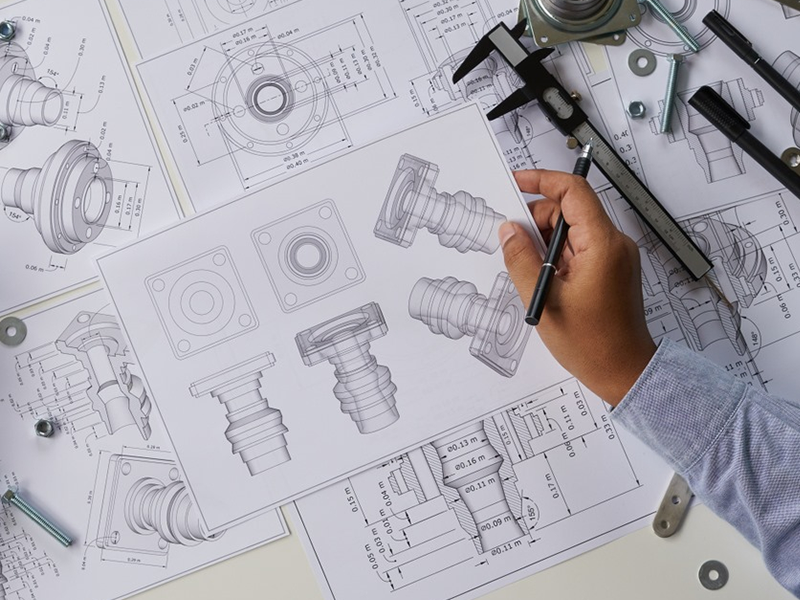

The Role of Manufacturing Drawing Software in Visual Communication

Manufacturing drawings are essential in product designs . Drawings like 2D manufacturing drawings and 3D mechanical drawings improve efficiency and lower errors in the manufacturing process by serving as a powerful communication tool for all parties involved. Therefore, using manufacturing drawings, you can save a lot of money and materials and obtain a product that meets all requirements.

This blog post will simplify a manufacturing drawing to be understood more easily.

Just dig in

What is a Manufacturing Drawing?

Manufacturing drawings are precise illustrations that guide the manufacturing of parts or objects. They offer exact specifications, such as dimensions, materials, tolerances, and assembly specifications, which are vital communication tools between manufacturers and designers. The drawings will ensure that the final product aligns with the design intent and the quality standards.

Designers use 3D mechanical drawing software to design, sketch, validate, and share ideas before production. Additional tools are offered and sometimes integrated into 3D engineering software to manufacture products using the CNC device and 3D printing. Mechanical drawing software is used in various industries, including automotive, industrial machine, and consumer design.

Deep drawing manufacturing is a standard method used in the industry to manufacture products. Complex parts can be achieved using deep drawing. The manufacturing process is widely employed in many sectors, including the automobile industry, the packaging industry, aviation, model construction, and the packaging industry. The most frequently produced deep-drawn components are car body parts faucets, bathtubs, and faucets, cooking pots, sinks, and plastic buckets.

Evolution of Drawings -Manufacturing Drawings

Before the initial release of the Computer-Aided Design (CAD) software program, Shop Drawings, Construction Drawings, and Installed Drawings were drawn by hand.

Do you remember offices with drawing boards, pencil sets, set squares, and erasers?

These are all things of the past; as technology has advanced, the drawings have also changed. Today, we can design buildings, machines, and products with particular characteristics in 2D and 3D graphics.

As CAD technology improved, the requirement for paper-based documentation diminished because the meta-data was recorded in systems. This increased efficiency increased projects in the form of 3D models incorporated into digital designs.

Suppose you think about the mess of managing huge piles of physical drawings on paper with notes on manufacturing. In that case, It's clear why digital systems started becoming the primary source for collecting product data.

Moving it up a notch makes it much more helpful when engineers are equipped with models, drawings, and descriptive designs. Visuals have become an essential element of product or manufacturing design because they enable engineers to comprehend what a final product or component will appear at a higher level of abstraction instead of requiring them to draw a picture of design and function from an inventory of manufacturing specifications.

Manufacturing drawings, including detailed specifications for components. Manufacturers, suppliers, and contractors utilize these drawings to comprehend the materials needed for production and the procedures to be followed during on-site installation and delivery of these components.

Is it quite interesting?

What makes a well-designed drawing software essential to manufacturing any item?

In short, it has advantages!

Advantages of Manufacturing Drawing -Navigating the World of 2D Manufacturing and 3D Mechanical Drawings

A well-designed set of drawings is essential to ensure efficient and cost-effective manufacturing. If you don't have a good idea, it could result in unsellable products or a manufacturing company that isn't willing to collaborate alongside you and a lack of direction for the future.

New designs for new products typically begin with a sketch of a hand that leads to more precise 3D models and even detailed manufacturing sketches.

Let's see what are the advantages of Manufacturing drawings!

Better communication

Manufacturing drawings are a method of communication between the maker and its owner. Therefore, it has to communicate the intent of the design to the maker in a way that they can comprehend.

Any crucial information that needs to be included could result in manufacturers relying on different standards or experiences to fill in the gap. This is a potentially tricky scenario since manufacturers only sometimes have a complete picture of the design or how it will interact with other components or equipment.

A professional and precise technical drawing provides all pertinent manufacturing details so that there is no confusion. Detailed part drawings coupled with a 3D manufacturing engineering drawing overview give the most effective of both sufficient detail to design the components correctly and an additional visual aid in understanding the larger picture.

Reduction in manufacturing time

A professional manufacturing drawing can significantly speed up manufacturing and save time in making corrections to errors.

If sketchy drawings are provided to manufacturers, they may have to create the pictures themselves to permit their employees to develop components. This can lead to long delays as the manufacturer must learn how everything works, and customers could be bombarded with inquiries during the procedure.

If the manufacturer uses a sketch that is not of the highest quality, it will be worse. The parts and products will be in a mess, with incorrect dimensions, finishes, fit and other mistakes due to poor drawings that could take weeks or even months to fix.

Whenever an explanation is required on an image, it can result in financial and time loss. Both the designer and the client must put off work to clarify what could have easily been included in the sketch.

Improvement in quality control

Controlling quality is essential for ensuring that the product conforms with its manufacturer and is consistent.

Manufacturing drawings are utilized together with inspection checklists and tests to make manufacturers accountable and clearly convey requirements. If a product requires a particular tolerance (such as when it needs to be compatible with other parts or equipment) It must be correctly calculated and documented precisely on the sketch. When the company's QC representative has signed off on the item, they verify that the part complies with the tolerances listed in the drawing.

If there is no tolerance data, a manufacturer may be required to follow each dimension of a plan as closely as they can. They believe these dimensions will be used to determine which parts to accept or not components. They could also think critical dimensions are unimportant and result in expensive work rework.

Precision dimensions are not always required. A professional designer will be able to calculate the most tolerant tolerance of a specific component or task to ensure the most efficient and cost-effective manufacturing. Inadequate high-precision dimensions (commonly included to cut design time) can cause confusion and add cost.

The ease of switching manufacturers

Any manufacturer must widely understand a quality manufacturing drawings. This implies that if one produces inferior components, consistently delays deadlines, or increases prices, the same picture can be referred to a different manufacturer, and the work can be carried on.

This is a further reason to hand over the creation of drawings for manufacturing to the manufacturer. They could use internal illustrations to influence negotiations, demand excessive charges for graphics or declare ownership of the pictures.

The result is that customers are often locked in with the manufacturers, who can determine the terms of their relationship.

Product design updates

After a product is prototyped, there will be changes, and the drawings set has to be updated to reflect any modifications that might have been necessary for manufacturing or functional purposes.

Up-to-date drawings can be essential if revisions need to be made following field performance evaluations.

For the upcoming software edition, the proper drawing set can help reduce time spent on duplicate work.

A poor set of drawings lost digital data, or a designer unable to reach them could make it easier to alter an item. Sometimes, creating the complete drawing set is the only way to progress. Investing in an expert set of designs initially comes with more than a professional layout. It can also save enormous amounts of money and time in the longer term.

Closing Thoughts

Making a quality set of drawings is essential in developing a product. Aliber manufacturing design software tool improves your process and prevents uncontrollable time frames and huge rework costs.

Contact us if you require manufacturing drawing software and learn about our products.

3D CAD Software

7 months, 2 weeks

How do we choose the best software for sheet metal design?

Choosing the best sheet metal design software is the most crucial element in sheet metal fabrication.

As the name implies, sheet metal must be formed into flat, thin pieces by combining a small amount of aluminum, steel, brass, copper, and various other materials. It can be cut precisely and formed into sheets, plates, or foils due to its distinctive features.

Sheet metal design involves shaping sheet metal into equipment, parts, assemblies, and products. Alibre Design software automates this process by enabling the automation of sheet metal design, nesting components, and generating CNC tool paths. Specifically designed for sheet metal, the software supports the engineering, modification, and optimization of sheet metal parts, along with creating manufacturing instructions and documentation.

In this article, we’re delving into the sheet metal manufacturing industry in the context of how metal design software can help guide this sector toward the future.

Why do you choose the best software for sheet metal design ?

Alibre's sheet metal design software integrates both 2D and 3D design features, enabling engineers and designers to craft accurate models of sheet metal components. Users can specify details like material thickness, bend allowances, hole sizes, and other geometric features crucial for sheet metal fabrication.

Simplify your design with Alibre software, the best CAD software for metal fabrication process. It seamlessly connects 2D and 3D workflows, allowing you to efficiently create, modify, and document sheet metal designs. This streamlined approach facilitates the swift transition of flat patterns into production.

Let us briefly list the top 5 benefits of choosing sheet metal design.

- Sheet metal products are relatively less expensive and more straightforward to manufacture but are used in forming processes.

- Manufacturing can be done on a smaller scale, not requiring a high-end machine. A hydraulic press uses various tools to form a sheet metal product for many processes.

- Cutting technology for CNC plasma has been added to the capabilities of sheet metal thanks to its precision and automation—cutting off any form.

- Sheet metal works efficiently because of the more straightforward procedures you have for drilling a hole, such as in the case of solids. However, in the case of sheet metal, you need to punch holes. Drilling is necessary to create a slot within a solid, but in sheet metal, CNC plasma cutting or a punch will complete the task.

- It is said that the weight of sheet metal-designed products is much smaller, which is the reason most enclosures are constructed of sheet metal, and most aluminum sheets are utilized because of their higher strength-to-weight ratio.

Alibre Design Software - The best CAD software for your Sheet Metal Design Needs

There are a variety of products that offer procedures that are related to sheet metal manufacturing design and other similar businesses. Manufacturers and engineers have been using specific drawing tools that create design information.

Compared to the real world (solid form), sheet metal pieces are usually created by 2D models using processes like cutting, bending, and welding.

Since sheet metal design differs from solid modeling, software designers should incorporate specific regulations into their designs. This allows the designer to convert the programmed format into metal sheet components.

Furthermore, by using the appropriate tools for design and modeling, you can reduce or eliminate mistakes and get your design to life promptly. Design flaws and delays typically cause the loss of time, waste of materials, and a decrease in profitability, which is detrimental to the company.

For a business that struggles to deal with shrinking resources, choosing the best software for CAD can be an issue of life or death. Utilizing these modern tools will help reduce changes in engineering (ECO) design errors and other mistakes that designers often create.

Here are five things to keep in mind when choosing the best CAD software for creating sheet metal

1. Sheet Metal Design Ability

Designers and engineers who can design sheet metal should ensure that the CAD program they purchase is compatible with their current software.Otherwise, the buyer could begin with a new project. The initial goal was to establish sheet metal compatibility with the CAD layout of the purchase. But, no one CAD software can satisfy all of your design requirements. This is the reality that everyone should accept.

Additionally, some of the most modern CAD tools available today might work differently than your current ones. There are now a variety of CAD modeling platforms with sheet metal design capabilities that can be used to create 3D models. Several CAD platforms can transform the solid model into metal sheets and add plane patterns.

2. DFM Regulations

A CAD system that is designed with manufacturing (DFM) capabilities will boost efficiency while also reducing the amount of time wasted. The DFM function should be utilized to create sheet metal products since it can ensure the plan's operation before submitting an item to a workshop.

The latest technology in CAD allows designers to revise their designs and conduct final checks before the actual production.

3. Ability to Handle Different File Formats

Engineers and designers should remember they are not alone. One of the primary reasons to choose a CAD system for designing sheet metal is that it can manage and store different file formats. Even the most prominent companies involved in this kind of business ought to adhere to this method, as they could have a wide variety of software suppliers that will help them make a lot of designs.

4. More Effective and Lasting Tools

Selecting a program specifically designed for processing sheet metal is the best reason. Although the program is written in 3D, most sheet metal designs typically include 2D engineering sketches. However, the 3D model may not accurately represent other specifications and dimensions (such as tolerances, surface finishes, etc. ). More specifics are required after the foundation has been laid.

5. Shorter Program Learning Time

Select a program that users can master in the shortest period ("short the learning curve"). If the user can't figure out how to integrate it properly in their local system, then even the most sophisticated CAD software in the world might need to be more powerful.

Alibre Design software offers numerous advantages to users engaged in sheet metal fabrication and manufacturing. Key benefits encompass optimized material usage, time efficiency, enhanced production processes, cost savings, seamless design-to-manufacturing integration, and compatibility with diverse fabrication methods.

Try our metal fabrication design software free

What are the production methods utilized in crafting sheet metal designs?

Water Jet Cutting:

Utilizing pressurized water mixed with abrasives, this method can efficiently cut through a variety of materials including stainless steel, Inconel, titanium, aluminum, tool steel, ceramics, granite, and armor plate, resulting in a clean edge finish.

Laser Cutting:

Involving the transmission of a gas laser, like CO2, through a precisely guided beam directed at the material, laser cutting achieves an exceptionally high level of precision.

Plasma Cutting:

The plasma process employs electrically conductive gas to transfer energy from a torch to the material, making it suitable for cutting metals like stainless steel, aluminum, and copper, especially those that cannot be flame cut.

Wrapping Up

As the challenges increase and the need for accuracy and efficiency increases, businesses must remain ahead of the technological curve.

Alibre Design is the best software for sheet metal design. This 3D CAD Software promises improved efficiency, reduced errors, and enhanced collaboration.

Are you ready to propel your processes for production ahead?

Contact Alibre today to take the sheet metal production process to new levels.

3D CAD Software

7 months, 4 weeks

The Best CAD Software for 3D Printing in 2024 - Ultimate Guide

Welcoming you to the realm of CAD 3D printing, With the Best CAD Software for 3D Printing you can create your most imaginative ideas into reality in just a few hours. If you’re an engineer, designer, or just someone with a flair for creativity, it’s easy to see the fantastic potential of this technology. There are so many 3D printing companies offering the best price and quality.

How do you decide the one that is right for you?

Don’t worry!

In this comprehensive guide, we’ll cover all you need to know.

We’ll also provide the reasons why Aliber CAD software is the best option. So, kick back, relax, and get into the exciting industry of additive production!

Choosing the Best CAD Software for 3D Printing -Buying Guide

The selection of the appropriate and best CAD program for 3D printing depends on your level of experience and design needs. Look at the general tips below to decide the qualities to look for when choosing CAD software designed for 3D printing. Also, the things to be looking out for:

- Minimalism: Should the software be easy to use or feature-rich? If you want to model complicated functional assemblies, consider a program with more capabilities. But if you need an easy modeller, look for a program with more user-friendly controls.

- Customization: How flexible should the program be? Consider if you require features like sculpting, editing the history, direct printer connection, and many other options.

- Collaboration: Certain programs allow collaboration through cloud platforms on projects, and even real-time collaborative modeling. This feature requires a specific program specifically designed to enable cooperation.

- Format: File format(s) The file format compatibility is a crucial aspect of software for CAD. If there is an incompatibility between file formats and formats, then parts of the model could be lost during transfers, leading to long delays. If your file type isn’t compatible with the kind of your 3D printer, it won’t be able to print.

- Application: What is the 3D model required to do? Will it be strictly structural, or will technical drawings, simulations, technical analysis, or other elements be necessary? If it is used to print 3D printing, do you need additional slicer software or other AM functions?

- Cost-effective: Some programs are entirely free. Other premium software programs are sold as enterprise-level packages and cost a lot. Be aware of your budget and the program’s subscription plan before deciding on the best one.

The above list can help you think about the programs to print 3D models for your project.

Check out best free cad software for 3d printing

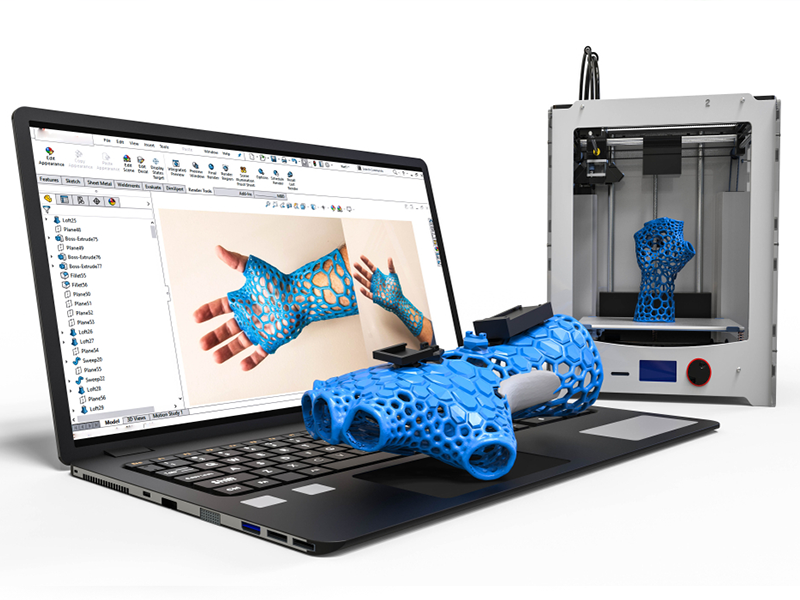

Introducing Alibre Atom3D -Best CAD Software for 3D Printing

Alibre Atom3D is a potent and easy best CAD software for 3D printing developed to meet the demands of hobbyists and professionals, and it is ideal for CNC 3D printing and hand tool work.

Alibre Atom3D is packed with powerful tools that make it easy to design, create, and export your designs for production. Here’s a brief overview of the key features that are part of Alibre Atom3D:

1. User-Friendly Interface

- Alibre Atom3D boasts an easy-to-navigate interface, making it available for experienced and novice designers.

- The intuitive menus and tools simplify designing, providing the smoothest and most efficient process.

2. Feature-Rich Modeling Tools

- The software has various modeling tools, allowing users to create complex and precise 3D models.

- The features include parametric modeling, assembly modeling, and powerful editing capabilities that allow for exact control of designs.

3. Parametric Design Capabilities

- Alibre Atom3D supports parametric design that allows designers to specify and alter design parameters easily.

- This feature improves the design adaptability, which makes it easier to modify models in response to evolving needs.

4. Versatile Applications

- Alibre Atom3D caters to various applications, including industrial and mechanical design, prototyping of products and more.

- This versatility is what makes it ideal for professionals in a variety of fields.

5. Incorporation of 3D Printers

- Alibre Atom3D integrates with 3D printing workflows and supports diverse file formats compatible with the most popular 3D printers.

- Users can design and visualize their designs to be suitable for 3D printing, ensuring a seamless transition from a 3D model in a digital model to a real prototype.

6. Affordability and Value

- Alibre Atom3D provides a cost-effective solution without sacrificing features or capabilities.

- Its price makes it an excellent choice for small businesses and individuals searching for CAD software with a robust design.

7. Community and Support

- The users who use Alibre Atom3D benefit from an active and friendly community.

- Detailed instructions, documentation, and quick customer support support the software.

8. Regular Updates and Improvements

- Alibre Atom3D developers consistently release updates that include new features and enhancements according to user feedback.

- Users can stay abreast of the most recent advancements in the field of CAD technology.

Tips and Tricks for Effective CAD Printing Design

Design with Printing in Mind:

- Consider the capabilities and limitations of your 3D printer during the design phase.

- Pay attention to print bed size, layer resolution, and support structures to ensure compatibility.

Optimize File Formats:

- Choose file formats compatible with your 3D printer, such as STL or OBJ.

- Regularly check and repair files using software tools to fix potential issues.

Mindful Layer Thickness:

- Adjust layer thickness based on the desired level of detail and printing speed.

- Find a balance between delicate details and printing time to optimize overall efficiency.

Support Structures and Overhangs:

- Incorporate support structures for overhanging features to prevent sagging or distortion during printing.

- Minimize the need for support when possible to reduce post-processing efforts.

Wall Thickness and Structural Integrity:

- Ensure adequate wall thickness for structural integrity, considering the material properties of your chosen filament.

- Use thicker walls for robust prints while avoiding excess material that may lead to printing issues.

Properly Orient Parts for Printing:

- Experiment with different orientations to minimize the need for support and improve overall print quality.

- Consider the natural flow of forces and stress in your design when positioning components.

Check and Calibrate Your Printer:

- Regularly calibrate your 3D printer to maintain accuracy and consistency in print quality.

- Monitor and adjust nozzle height, bed leveling, and extrusion settings.

Avoid Small and Fragile Features:

- Small, delicate features may not print accurately or may break easily.

- Opt for more extensive, sturdier structures and consider assembly for intricate details.

Printability Test Prints:

- Before committing to a large print, conduct test prints of critical sections to identify potential issues early on.

- Adjust settings as needed and fine-tune the design before the final print.

Post-Processing Considerations:

- When designing your model, plan for post-processing steps, such as sanding or painting.

- Factor in additional material for post-processing, especially for smoothing or finishing touches.

Material Selection:

- Choose the appropriate filament material for your project, considering strength, flexibility, and temperature resistance.

- Be aware of material-specific printing requirements and adjust designs accordingly.

Documentation and Version Control:

- Keep detailed notes on your design iterations and settings for future reference.

- Implement version control for your design files to track changes and improvements.

By incorporating these tips and tricks into your 3D printing design process, you can enhance the printability of your models, reduce errors, and achieve optimal results with efficiency.

Conclusion

Alibre Atom3D is an affordable and versatile CAD programs for 3d printing that allows users to bring their artistic designs to life using accuracy and speed. If you're an engineer in the professional field or just a casual user of the possibilities of 3D Modeling, Alibre Atom3D provides a user-friendly solution for all your design requirements.